Continuous demand to provide sustainable material solutions for future society is the main driver for our research. We aim is to gain knowledge on structural features and their influence on the materials performance to design innovative, sustainable, energy-efficient and safe materials. Another goal is to develop NDT practices for efficient quality control and performance evaluation of materials. These provide detailed material know-how to be exploited in real industrial applications.

Research focus and goals

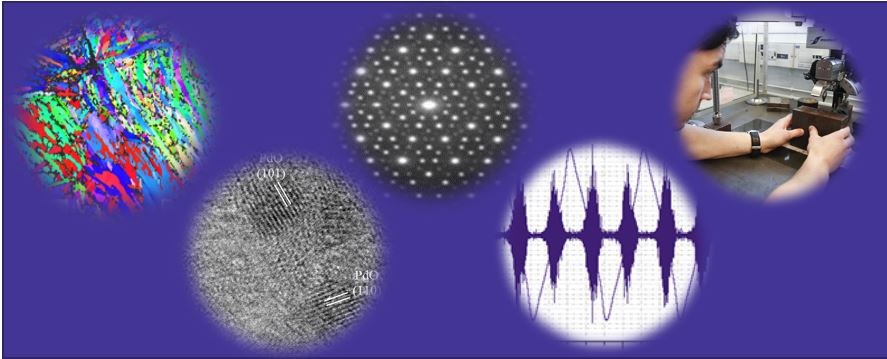

Our research groups research interests are wide-ranging in the area of materials characterization, main focus being on materials structural characteristics and their relation to other material properties and to non-destructive material performance evaluation. Research on detailed structural characteristics of various materials is based on utilization of multi-scale characterization methods including electron microscopy with microanalysis and electron diffraction techniques and X-ray diffraction analysis. Non-destructive testing enables the examination of a component without affecting to its future use. NDT methods (like magnetic Barkhausen noise and XRD) can be used e.g. for materials surface condition and residual stress evaluation.