Research infrastructure

Materials testing and characterization

Tampere University

Hervanta Campus

AddressKorkeakoulunkatu 6

Tampere

Materials testing and characterization

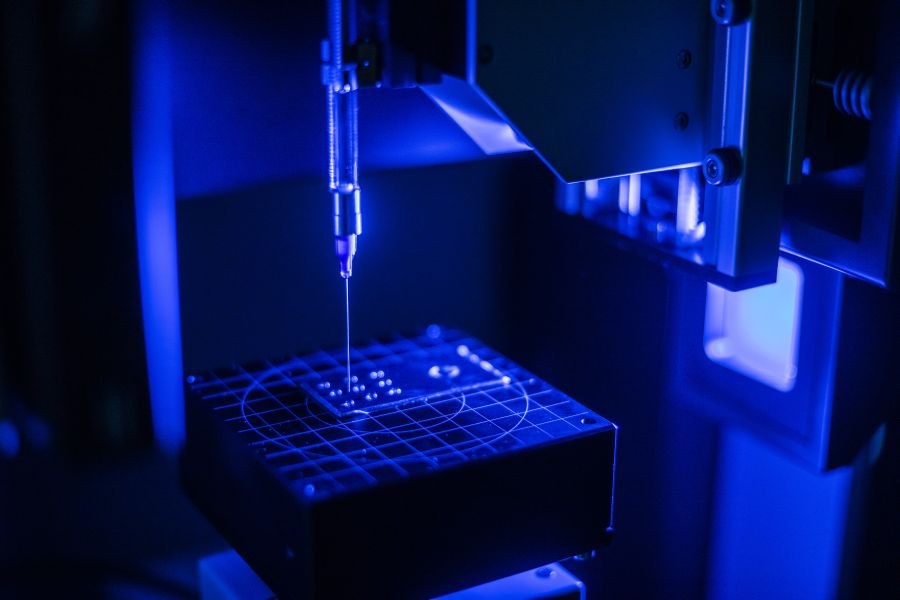

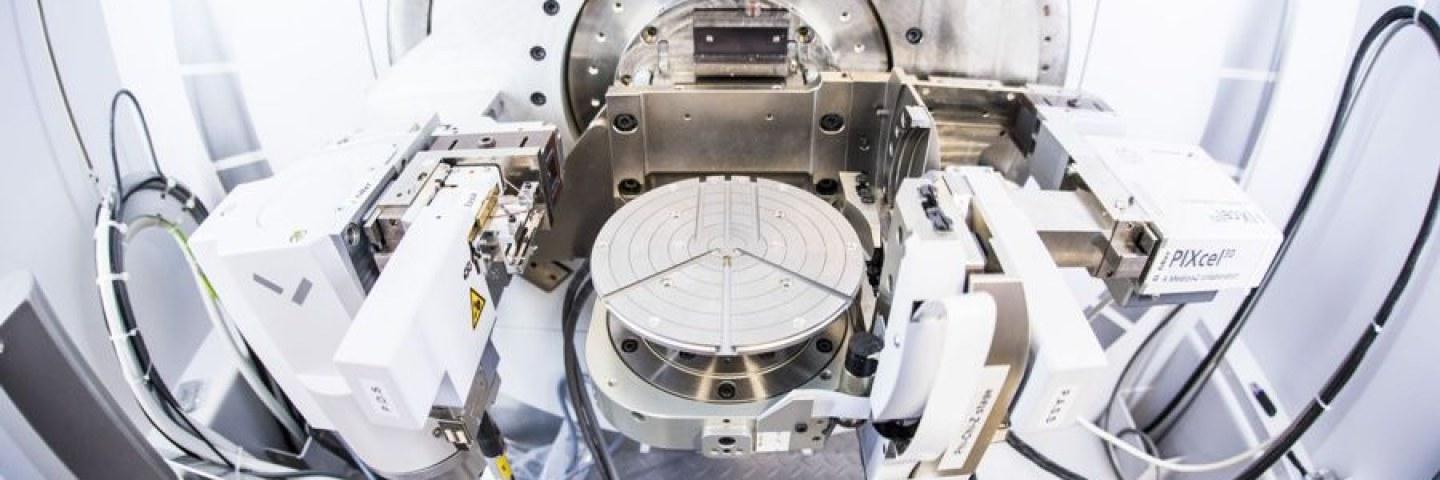

Materials characterization facilities include various optical microscopy techniques for structural and surface analysis, and X-ray diffractometry for phase, structure, and residual stress analysis. The multipurpose testing facilities include for example hardness testing, non-destructive testing, climate and corrosion testing, icing research and testing systems, and analysis of packaging materials. Well-equipped furnace laboratory provides possibilities for different heat treatments. There is also versatile software for the material and material property modelling.