Published

Antonia Ressler, Setareh Zakeri, Piie Konnunaho, Martin Schwentenwein, Erkki Levänen, Erkka J. Frankberg, Cleaning strategies for 3D-printed porous scaffolds used for bone regeneration fabricated via ceramic vat photopolymerization, Ceramics International 50 (2024) 53107-53119. https://www.sciencedirect.com/science/article/pii/S0272884224046741

Abstract

Vat photopolymerization has gained prominence in bone tissue engineering owing to its capability to fabricate intricate structures that closely mimic the natural bone tissue. Thorough cleaning of uncured ceramic slurry from the as-printed structures is essential, as the presence of residue within the structure can obstruct pores during sintering. Given the limitations of conventional spray cleaning for these structures, this study seeks to investigate alternative cleaning approaches. Specifically, the efficacy of dibasic ester (DBE) and LithaSol 80, coupled with ultrasonic and soaking methods, is examined to identify optimal strategies for the thorough removal of viscous residual slurry (LithaBone HA 480). To examine the effect of temperature on cleaning ability, printed scaffolds were soaked in the cleaning solutions at 23, 30, 40, and 50 °C for 24 h. Based on the results, 50 °C was chosen as the temperature for further analysis while using both soaking (24, 48, 72 and 96 h) and ultrasonic (5, 15 and 30 min; 1, 2, 3, and 4 h) as the cleaning methods. The cross-sectional image of the scaffolds showed that at least 48 h and 30 min is required for effective cleaning with soaking and ultrasonic, respectively. Microstructure analysis of scaffolds cleaned with LithaSol 80 revealed smoother surfaces, while scaffolds treated with DBE showed visibly contracted pores with peeling effect suggesting that DBE exerts a more aggressive action on the cured slurry in contrast to LithaSol 80. Notably, significant difference in mass loss was observed between scaffolds treated with LithaSol 80 and DBE. The significantly higher mass loss observed with DBE suggests that it not only impacts uncured slurry but also possibly affects cured slurry. Accordingly, the results indicate that DBE is notably more effective in cleaning; however, LithaSol 80 is more appropriate for maintaining structural integrity combined with soaking cleaning method. No significant difference was observed in compressive strength between most sintered scaffolds.

Antonia Ressler, Setareh Zakeri, Joana Dias, Markus Hannula, Jari Hyttinen, Hrvoje Ivanković, Marica Ivanković, Susanna Miettinen, Martin Schwentenwein, Erkki Levänen, Erkka J. Frankberg, Vat photopolymerization of biomimetic bone scaffolds based on Mg, Sr, Zn-substituted hydroxyapatite: Effect of sintering temperature, Ceramics International, Volume 50, Issue 15, 2024, 27403-27415, https://doi.org/10.1016/j.ceramint.2024.05.038. (open access)

Abstract

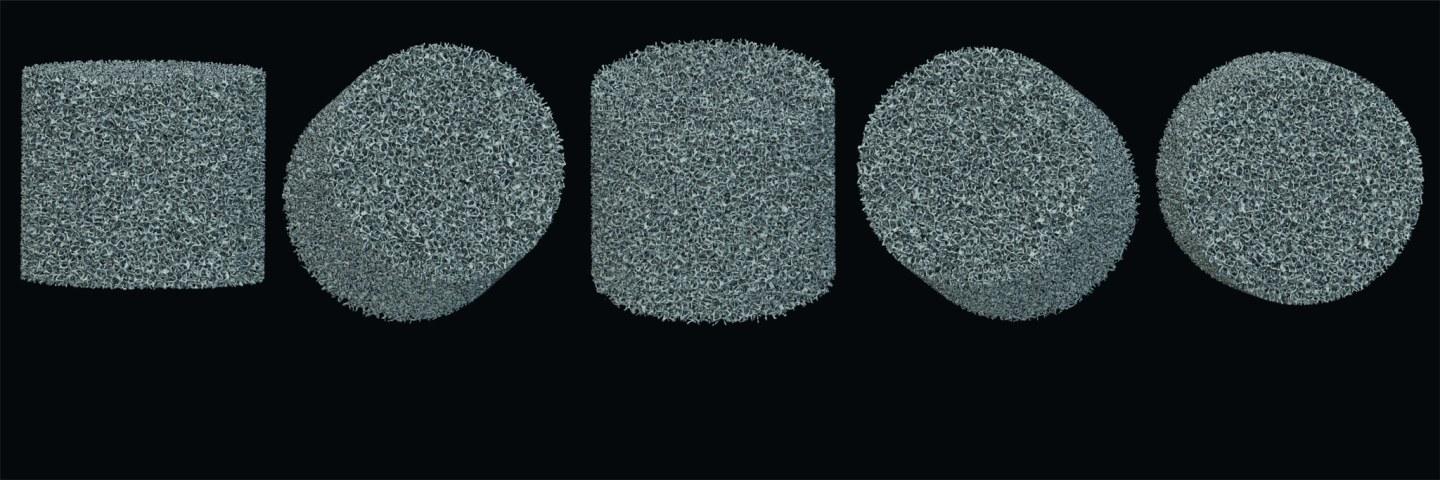

In response to the urgent demand for innovative bone regeneration solutions, the focus of this study is to develop and characterize Mg, Sr, Zn-substituted calcium phosphate scaffolds that replicate the trabecular architecture of cancellous bone. Ion substitution represents a promising approach to improve the biological effectiveness of calcium phosphates and composite materials used in bone tissue engineering applications. Porous scaffolds mimicking the natural bone structure were additively manufactured from the photosensitive ceramic suspensions for vat photopolymerization using digital light processing. The impact of the selected trace elements (0, 1 and 5 mol.% substitution) and the sintering temperature (900, 1000, 1100, 1200, and 1300 °C) was investigated in relation to the obtained crystalline phase content, microstructure, elemental distribution, thermal stability, and mechanical properties. After sintering, in addition to hydroxyapatite, β-tricalcium phosphate was detected as a result of the added trace elements in the calcium-deficient hydroxyapatite used as a starting powder. The obtained scaffolds exhibited uniform distribution of the trace elements, and they feature 3D-designed porosity predominantly ranged from 10 to 900 μm in diameter, with an average pore size of 546.25 ± 10.95 μm. The total porosity of scaffolds was 76.24 ± 1.32 vol% and an average wall thickness of 217.03 ± 8.98 μm, closely resembling the morphology of cancellous bone tissue. The mechanical properties of the scaffolds sintered at 1100 °C, 1200 °C, and 1300 °C were in line with those typically observed in trabecular bone. The study demonstrates the feasibility of using custom made bioactive hydroxyapatite powders together with vat photopolymerization to design the porosity and properties of the bone scaffolds on demand, based on the requirements of individual bone defects.

In the process of publishing

Antonia Resslera, Roope Ohlsbom, Setareh Zakeri, Markus Hannula, Arjen Gebraad, Toni-Karri Pakarinen, Jari Hyttinen, Erkki Levänen, Erkka J. Frankberg, Susanna Miettinen, Effect of porosity, sintering temperature, and trace elements on biomimetic bone scaffolds based on calcium phosphates obtained by ceramic vat polymerization.