Advanced mechanics of materials

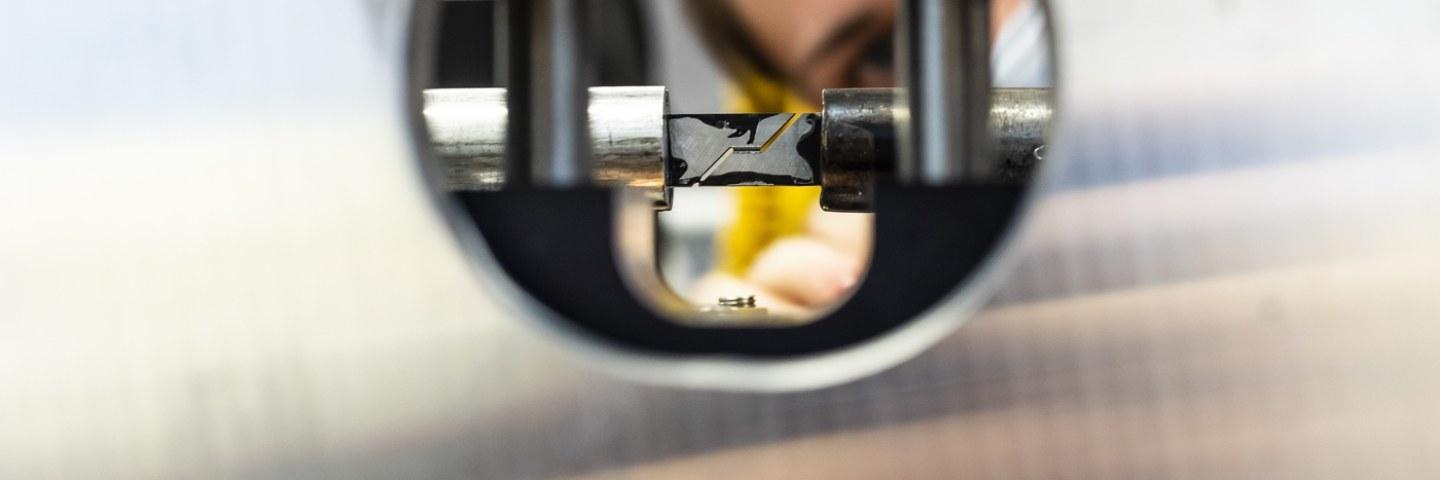

This research infrastructure facilitates characterization of mechanical behavior of all engineering and natural materials at wide range of conditions and length scales. The mechanical properties and behavior such as strength, failure, fatigue, etc. can be evaluated at microscopic length scales using in-situ micromechanics up to larger macroscopic component size. We can characterize material behavior at different temperatures from sub-zero close to melting temperatures of most metals. Equally we can cover a wide range of strain rates from creep to dynamic impact events. We specialize in using optical and infrared photography up to very high frame rates, and we routinely use digital image correlation and other in-situ characterization methods.