Optimising thermal management for electric vehicles – researchers develop efficient cooling system for motors

As conventional engine cooling systems are poorly suited for EV motors, Academy Research Fellow Payam Shams Ghahfarokhi is investigating the potential of an oil spray cooling system for high-power density EV motors.

In this system, oil is sprayed directly onto the stator end windings and rotor of an electric motor, serving as a coolant. This technique improves the efficiency of heat removal compared to conventional air or liquid cooling methods and also eliminates the risk of overheating.

To date, little research has been conducted on the applicability of oil spray cooling systems as a thermal management method for EV motors.

“The goal of this study is to create a standardised approach for designing an advanced oil spray cooling system. Our findings will promote the development of next-generation thermal management systems for EVs,” Shams Ghahfarokhi says.

“Our aim is to set a new industry standard for EV motor cooling”

Funded by the Research Council of Finland, Shams Ghahfarokhi’s study includes a thorough analysis of the oil spray cooling method for electric motors. The study was launched in 2023.

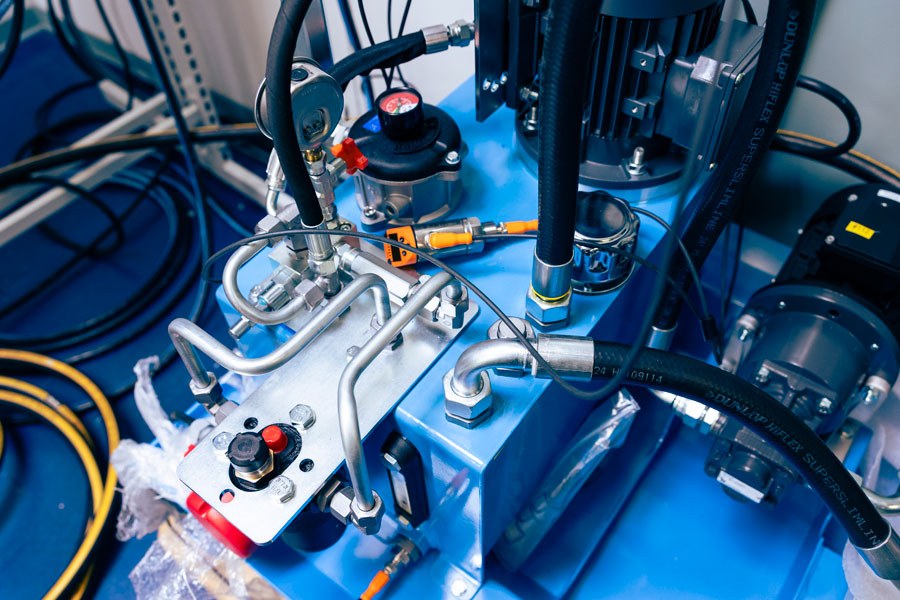

The researchers involved in the study are currently conducting empirical tests and measuring the heat transfer coefficients (HTC) of oil spray cooling. They are also developing mathematical models to predict cooling performance.

After the testing phase, they will shift their focus to the optimisation and validation of the system in the final stage of the study.

“We expect to have a fully validated oil spray cooling system for EV motors within the next couple of years,” Shams Ghahfarokhi says.

He states that the researchers’ long-term goal is to establish Tampere University as a leading research hub in EV thermal management by developing a centre of excellence for next generation cooling technologies.

“Our aim is to set a new industry standard for EV motor cooling, making this method the preferred choice worldwide. Strengthening long-term industry partnerships will ensure continuous innovation and development.”

“By bridging academia and industry, this research can lead to practical solutions that benefit businesses and consumers alike, ultimately turning groundbreaking scientific discoveries into real-world advancements that drive a more sustainable and efficient future for electric transportation,” Shams Ghahfarokhi continues.

Promoting the electrification of traffic

Shams Ghahfarokhi’s study contributes to sustainable development in many ways. More effective thermal management will increase efficiency, extend component lifespan, reduce material consumption and lower emissions.

These improvements will result in greener, longer-lasting and more energy-efficient electric vehicles. The study will also contribute to a more sustainable transportation ecosystem, supporting the transition to cleaner mobility and a reduced environmental footprint.

Moreover, the research results will accelerate the transition to electric traffic and encourage EV manufacturers to adopt smaller, more efficient and increasingly high-performance motors.

“For example, the optimisation of motor design will lower both production costs and energy loss,” Shams Ghahfarokhi says.

The study is conducted by the Electromechanics research group within the Faculty of Information Technology and Communication Sciences (ITC) at Tampere University, with funding provided by the Research Council of Finland.