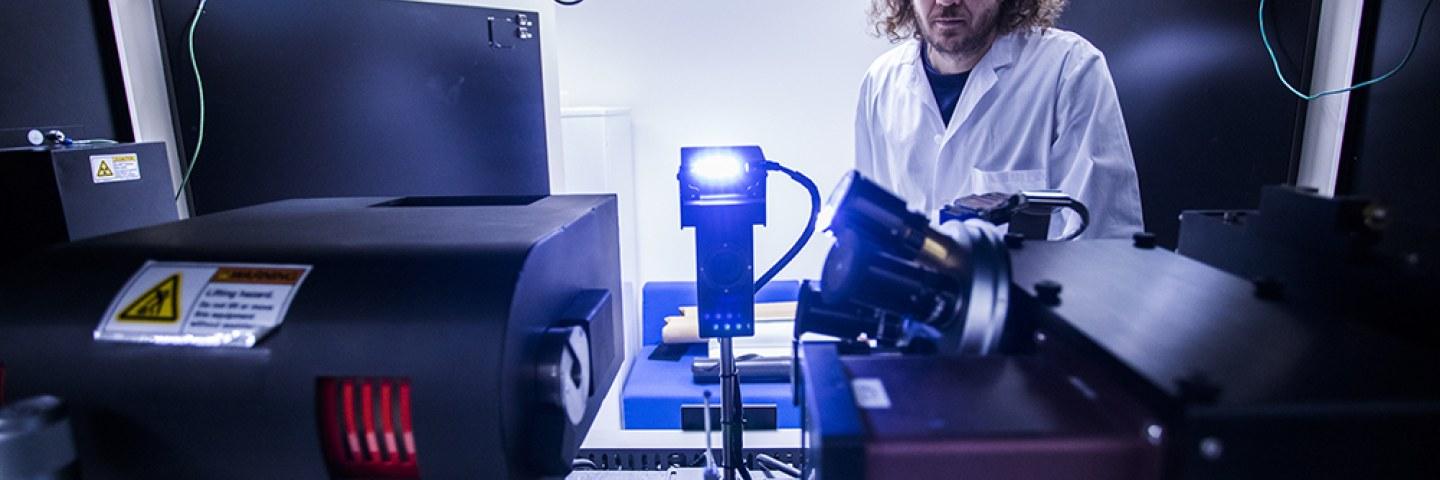

X-Ray Microtomography

The facility offers 3D imaging and assessment of structures of practically any materials, composites or devices including tissues and bio-constructs up to sub-micrometer resolution. The imaging is based on X-ray tomography and the facility has state-of-the-art image data processing and analysis workstation available for 3D-visualization, quantification, and surface and volume modelling.

Introduction

Our Zeiss Xradia microCT can be used to determine morphological parameters of materials, biomaterials and biological samples with resolution down to 1 micron. On the other hand, it can accommodate large samples in cm and dm scale at the expense of resolution. The variety of imaged samples is wide. So far, we have imaged bones, tissues, cells, small animals, scaffolds, biochars, circuit boards, medical implants, insects, filters and paper.

X-ray computed tomography, is a non-destructive means to create cross-sectional images of a three-dimensional object. The device takes hundreds of X-ray images around the object and calculates its internal 3D structure based on the density distribution of the material. Thus the contrast in X-ray-CT images is based on the density variation within the object and can be enhanced with various non-specific and specific contrast agents. Biological samples are often fixed because the imaging may take a few hours and X-rays can harm living cells.

The device is situated in Computational Biophysics and Imaging Group (CBIG) in the Tampere University, in Arvo building at the Kauppi campus.

In addition to the imaging system, the facility has state of the art data processing and analysis workstation available with visualization and 3D-image quantification possibilities with Avizo (https://www.fei.com/software/amira-avizo/). With this software and our own scripts we can visualize the sample and assess the sample material properties such as porosity, material thicknesses, pore sizes, their interconnectivity etc.

ACKNOWLEDGEMENT

Many of the technologies are still experimental and in development. Thus, prior to publishing, please agree the level of acknowledgement/participation of the paper with the core contact persons.