Tiny carbon nanotubes may play a significant role in binding atmospheric carbon dioxide

The researchers aim to promote sustainable electrification of society by exploring value chains and business opportunities related to hydrogen and carbon. The research is part of the HYGCEL – Hydrogen and Carbon Value Chains in Green Electrification project that promotes the use of sustainably produced hydrogen and carbon as part of the energy system, as a raw material for industry and as a fuel for green transport.

The researchers want to enhance carbon capture by specifically sequestering carbon into a solid form in which carbon is stored for decades. Carbon capture and storage (CCS) directly from emission sources, such as from pipes in factories or energy plants, uses up to four times less energy than direct air capture (DAC). A carbon sink based on solid carbon products is significantly more efficient than, for example, refining into a fuel.

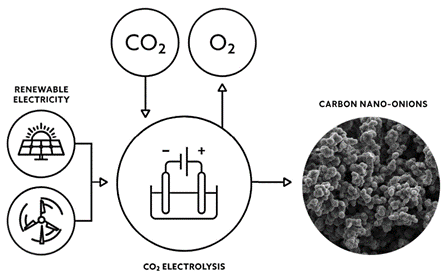

The production of solid carbon products can be seen in the latest research results. The researchers succeeded in developing a device that can be carbon-negative to produce a layered carbon structure, so-called carbon nano-onions, as well as carbon nanotubes and oxygen by the electrolysis of carbon dioxide. The materials were produced with renewable solar and wind energy.

A key research result is also the discovery of process parts that can withstand process conditions. They make it possible to move towards industrial application. In fact, the process is scaled to a larger size with continuous test equipment.

In the process, the carbon dioxide sequestered from emission sources is broken down into gaseous oxygen and solid carbon by a special molten salt electrolysis. As a result, carbon nanotubes are formed, which are used in the manufacture of batteries or new ultralight materials such as airplane wings and wind turbines. At best, carbon nanotubes are very valuable, even thousands of euros per gram. In industrial applications, the price is estimated at tens of thousands of euros per tonne.

Carbon products in great demand globally

According to Professor of Practice Tero Joronen, who leads the study of the Solid carbon products from CO2 at Tampere University, sustainable solid carbon products have a high carbon sink potential and a significant global market.

“The key is to turn CO2 emissions into negative, i.e., carbon sinks. That is why we are developing sustainable materials to which carbon dioxide binds for a long time. According to market research we conducted, carbon capture has a market potential of EUR 2.5 billion. When carbon dioxide is refined into valuable products, the potential multiplies,” Joronen says.

Bio-based carbon dioxide generated in the forest industry could be sequestered from flue gases. Currently, two thirds of the carbon from the wood entering the pulp mill is released as carbon-neutral CO2 emissions into the air. The emissions would become negative if carbon dioxide were recovered from the factory’s flue gases and utilised for durable products.

“There would be a boost in the fight against climate change if the carbon dioxide bound in the forest would be used in such a way that it does not return to the atmosphere but is used as a carbon sink product or stored permanently. Finland’s rocky soils are not naturally suitable for carbon storage, so it is worth investing in sustainable carbon products here,” he notes.

The scale available to offset emissions is huge. According to Joronen, the calculations show that if all CO2 emissions from domestic pulp and heat production were recovered, Finland’s total emissions, i.e., approximately 40 million tonnes of carbon dioxide, could be compensated.

The research funded by Business Finland is partnered by LUT University and CLIC Innovation, which operates at the interface between industry and research. The research project will end by the end of May 2024.

Text: Anna Aatinen

Contact person

Tero Joronen

Principal Researcher Tero Joronen

Tero Joronen