Tribology and wear testing

Tribology and wear testing infrastructure

Tampere Wear Center (TWC) concentrates on both scientific and practical aspects of wear and tribology, bridging the gap between scientific basic research and applied industrial research and product development. The aim of TWC is to provide in-depth insight into the mechanisms of wear and thereby facilitate the development of new wear resistant materials and to find solutions to the practical wear problems constantly faced by the industry. TWC conducts research in close collaboration with several internationally recognized partners.

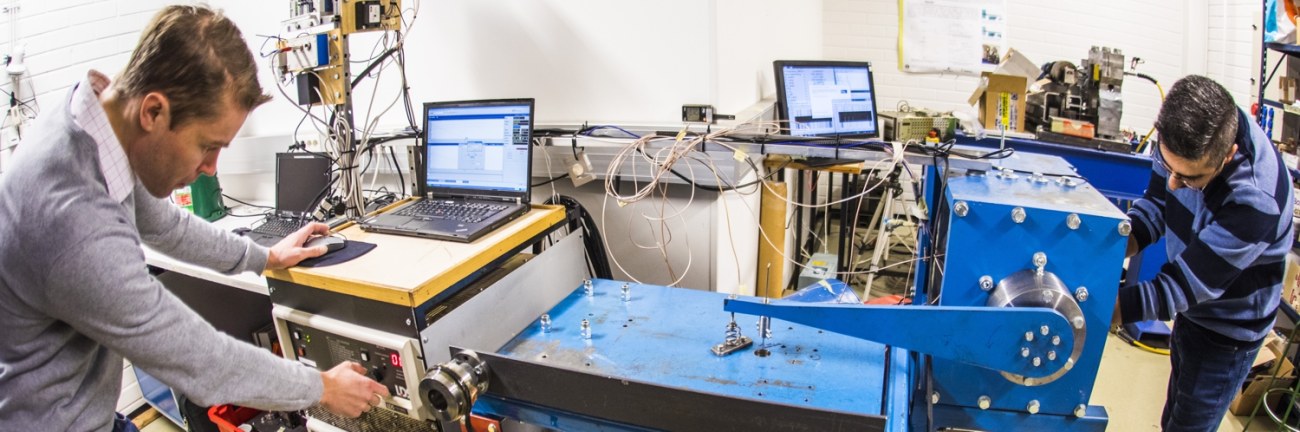

TWC has excellent infrastructure for wear and tribology research, as well as highly qualified scientists and research engineers for the needs of both long-term scientific research and product development for the industry. The TWC infrastructure has facilities for wear and tribology testing, including heavy abrasion, impact wear, slurry-erosion, fretting and tribology of machine elements, such as gears, bearings, and frictional joints. The equipment is designed and built to simulate the in-service conditions. The facilities cover also vibration monitoring and diagnostics of machine systems.