Small and agile robot miners shape the future of mining industry

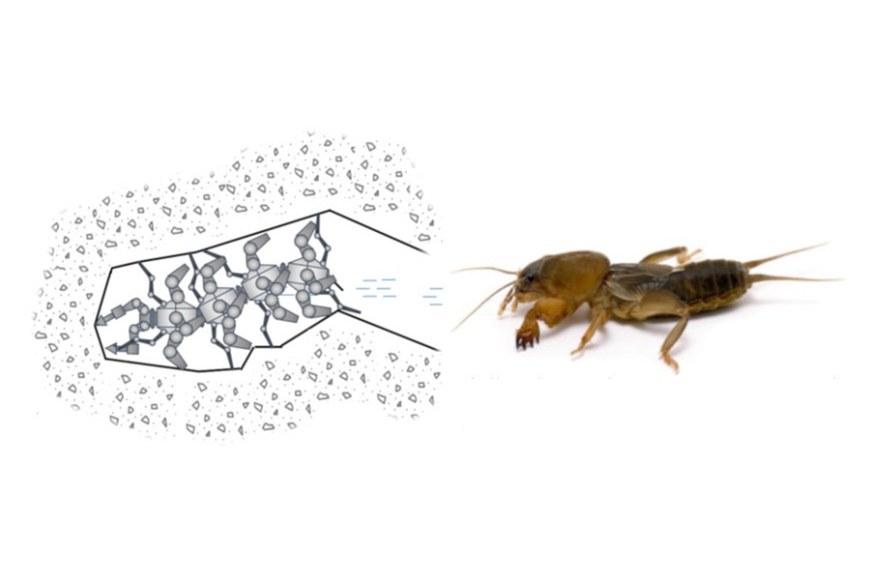

The four-year ROBOMINERS project will focus on the development of a next generation mine that is based on autonomous robot miners and allows mining even small and elusive mineral deposits. These autonomous robot miners are small, modular and bio-inspired. Another special trait of the prototype is its ability to use modules to self-construct and also self-reconfigure for various tasks. Therefore, only a narrow mine shaft is needed to take the required parts underground.

”Our research could revolutionise the entire mining industry. Going forward, we may not need massive mining areas but simply use small robots that take care of the underground work and mine the deposits with precision and without harming the environment,” says Professor Kari T. Koskinen from Tampere University.

The developed robot miner will also be able to work in underwater environments. This means additional environmental benefits and notable cost-savings, as it may no longer be necessary to pump mines empty of water. This, in turn, reduces the amount of wastewater to be processed. Also, massive piles of waste rock would no longer be created, since the robot only mines the required materials. Any small waste rock residues could be used to refill mined areas.

Various artificial intelligence and machine learning applications will be applied in the robots to help them move about in the mine and identify the minerals to be mined.

”One example of all-new sensors are our artificial antennae of sorts, with which the robot observes its surroundings,” Koskinen notes.

The ROBOMINERS project has arisen from the concern about Europe’s self-sufficiency and security of supply. With the robots, it would be possible to access remaining deposits in former mining sites originally mined using traditional methods.

At the heart of Tampere-based expertise

Professor Kari T. Koskinen and Research Manager Jussi Aaltonen from Tampere University’s Mechatronics Research Group are both closely involved in the project. They are excited about the great potential advancement steps to be taken in the project as well as Tampere-oriented research aspects.

”We have plenty of expertise when it comes to applying multiple technical systems in mechanical engineering, and this project will allow us to use it in many ways. ROBOMINERS also involves investigations of various methods for new actuator types and their adjustments. This area will involve enough work for several doctoral researchers, for example. The robot miner is thus a genuine research project, not merely an engineering solution to an existing problem.”

”Interdisciplinary work also plays a strong role here, as in addition to engineers, the project researchers include geologists. A previous project of ours, UNEXMIN, involved archeologists and brought us plenty of useful knowledge about the mining industry,” Jussi Aaltonen says.

ROBOMINERS is a large-scale project led by the Spanish Universidad Politecnica de Madrid university. The project involves 12 other partners besides Tampere University, including universities, research institutions and businesses.

Further information:

Professor Kari T. Koskinen tel. +358 400 634 242, kari.koskinen [at] tuni.fi

Research Manager Jussi Aaltonen tel. +358 40 8490522, jussi.aaltonen [at] tuni.fi